Waterjet cutting

Detail production in both hard and soft materials

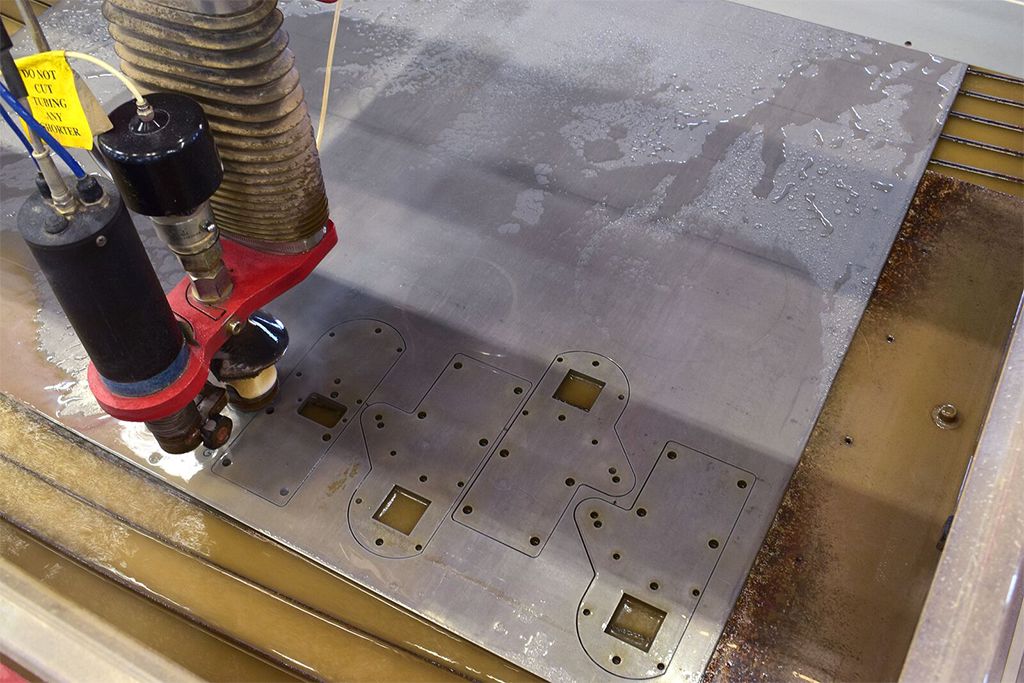

For us at Bofab, it is important that you can be sure of the quality and function of our products. That is why we build our belt conveyors, chain conveyors, roller conveyors, and spiral conveyors under our own roof, from drawing to finished product. And an important part to be able to ensure this, we use waterjet cutting in our detail production. Waterjet cutting is a processing method that can cut into a variety of materials with only water and sand without damaging the material, which can easily happen with, for example, laser cutting.

Do you need to get details to your production quickly and efficiently? And without damaging the material? Then waterjet cutting is the solution for you. In short, it is a unique processing method we can offer you. Basically, we can cut in a variety of materials. But we do so with just water and sand!

What is Waterjet cutting?

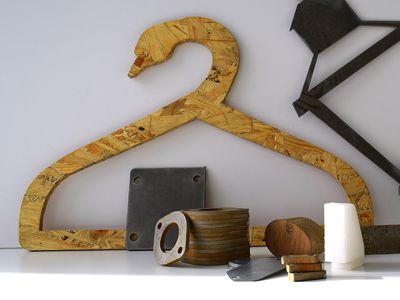

Waterjet cutting i a method for cutting various materials with a strong jet of water. And mix that jet beam with sand you get water jet abrasive cutting. Combined the cutting effect of the jet increases. So it is a very special production process. It is a gentle technique as it cuts without damaging the material. And does not affect the material’s properties when cutting. For example due to heat deformations. In this case because the machine uses cold machining. Waterjet cutting lets us cut soft materials as rubber, plastic and wood. And in hard materials like stainless steel, titanium, ceramics, composite and stone materials.

A method for cutting various materials with a strong water jet. And mix that jet beam with sand you get water jet abrasive cutting. Combined the cutting effect of the jet increases. So it is a very special production process. It is a gentle technique as it cuts without damaging the material. And does not affect the material’s properties when cutting. For example due to heat deformations. In this case because the machine uses cold machining. Waterjet cutting lets us cut soft materials as rubber, plastic and wood. And in hard materials like stainless steel, titanium, ceramics, composite and stone materials.

Also, we use waterjet cutting for our own production of conveyors. Details like motor plates, leg stands, funnels etc. Our main business is belt conveyors, chain conveyors, roller conveyors and spiral conveyors.

Benefits of waterjet cutting

- Cutting and punching with the same tool

- Gentle on the material

- Easy to process after cutting, such as threads, etc.

- No harmful gases and vapors

- No thermal or chemical damage

- 0.2-1.5 mm wide cutting beam = minimal waste of material

- No stresses or micro cracking in the material

- High quality of the cut edges of the material – finishing is rarely required

- Gentle on alloys

- The cutting edges are easy to paint

- Cutting and punching with the same tool

- Gentle on the material

- Easy to process after cutting, such as threads, etc.

- No harmful gases and vapors

- No thermal or chemical damage

- 0.2-1.5 mm wide cutting beam = minimal waste of material

- No stresses or micro cracking in the material

- High quality of the cut edges of the material – finishing is rarely required

- Gentle on alloys

- The cutting edges are easy to paint

![Transportörer för alla behov – Bofab Conveyor AB[:en]Conveyor for all needs – Bofab Conveyor [:]](https://www.bofabconveyor.se/wp-content/uploads/logga-bofab.png)